Welcome To CB Piping System Co., ltd., ...

The Essential Guide to Lignite Drying Production Lines: Enhancing Efficiency in Industrial Drying Processes

Release time:

2025-08-13

A lignite drying production line employs advanced drying technologies to reduce the moisture content in lignite.

Lignite, often referred to as brown coal, is a type of coal that is typically low in carbon content and high in moisture. Due to its high moisture levels, it poses challenges for transportation and combustion efficiency. This is where a lignite drying production line comes into play, offering a critical solution to optimize lignite's usability in various industrial applications.

A lignite drying production line employs advanced drying technologies to reduce the moisture content in lignite. This process is essential in enhancing the calorific value of lignite, making it more efficient as a fuel source. The drying process typically uses heat to evaporate moisture, ensuring that the lignite can be utilized effectively in power generation or as a raw material in industrial processes.

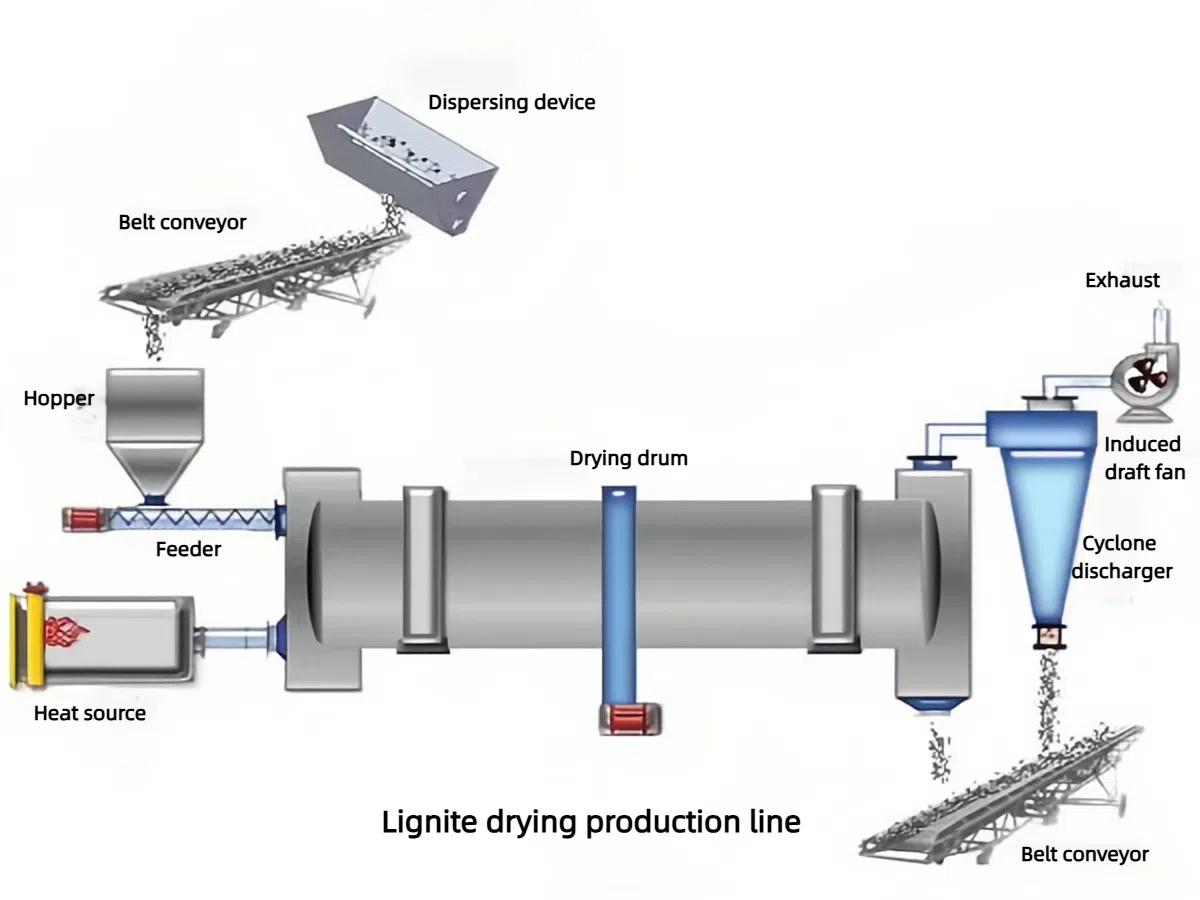

One of the key components of a lignite drying production line is the drying equipment itself. Various methods can be employed, including rotary dryers, fluidized bed dryers, or belt dryers, depending on the specific requirements of the operation. These drying methods utilize different mechanisms to ensure that the lignite is dried evenly and efficiently, ultimately leading to improved product quality.

The benefits of utilizing a lignite drying production line are multifaceted. First and foremost, reducing moisture content increases the energy efficiency of the lignite, resulting in higher output during combustion. This not only maximizes the energy potential of the lignite but also reduces emissions during burning, contributing to a more environmentally friendly operation. Additionally, lowering moisture content can minimize transport costs, as dried lignite is lighter and requires less energy for transportation.

Moreover, implementing a lignite drying production line can help industries comply with stricter environmental regulations. By enhancing the energy content and reducing emissions associated with lignite use, companies can better align their operations with sustainability goals while also improving their overall competitiveness in the market.

In summary, lignite drying production lines are indispensable in the realm of industrial drying equipment. Their role in improving lignite's usability by significantly lowering moisture content cannot be overstated. As industries continue to seek more efficient and sustainable methods for utilizing coal-based products, lignite drying production lines will play a pivotal role in shaping the future of energy production and industrial processes. By investing in advanced drying technologies, companies can enhance their operational efficiencies, reduce costs, and contribute to a more sustainable industrial ecosystem.