Welcome To CB Piping System Co., ltd., ...

2025 Qingdao Asia - Pacific Rubber & Plastics Expo Concludes Successfully, Our Rubber Drying Technology Takes Center Stage

Release time:

2025-07-15

2025 Qingdao Asia - Pacific Rubber & Plastics Expo: Our efficient rubber drying furnace with heat recycling shines, cutting costs & ensuring quality.

The four - day Qingdao Asia - Pacific Rubber & Plastics Expo 2025 was successfully held at Qingdao World Expo City from July 10th to 12th, 2025. This industry event attracted 1,578 exhibitors from around the globe, covering an exhibition area of 80,000 square meters. It showcased over 8,000 high - end products including rubber raw materials, mechanical equipment, and tires, establishing a highly valuable platform for exchange and cooperation in the global rubber and tire industry.

During the expo, a series of exciting activities were held. The Award Ceremony for the Top 50 Enterprises in Comprehensive Strength of Shandong's Rubber Industry was grandly held, honoring outstanding enterprises in the industry and injecting strong impetus into the development of the entire sector. Meanwhile, more than 10 professional forums such as the "Innovation - Driven · Intelligence Leading the Future" Industry Development Forum and the 2025 Synthetic Rubber Innovation and Application Conference were successfully organized. Numerous industry experts, scholars, and enterprise representatives actively participated, discussing cutting - edge industry trends and sharing the latest technological achievements and innovative ideas.

Notably, this expo set up a cross - border procurement matching zone for the first time, achieving remarkable results. 162 purchasers from countries and regions including the United States, Italy, Brazil, Mexico, and Russia conducted on - site negotiations with enterprises in the province, reaching over 120 cooperation intentions on the spot, with an estimated transaction volume exceeding 14.57 billion yuan. This outcome not only strongly promoted trade cooperation between domestic and foreign enterprises but also further enhanced the influence of the Qingdao Asia - Pacific Rubber & Plastics Expo in the international market.

At this expo, the rubber drying - dedicated hot air furnace, rubber drying design scheme, and rubber drying process brought by our company became the focus of attention. In the rubber production process, the drying treatment of rubber particles is crucial, and the temperature during drying must not be too high, requiring a low - temperature slow drying method. However, traditional drying methods suffer from low thermal efficiency and significant heat loss.

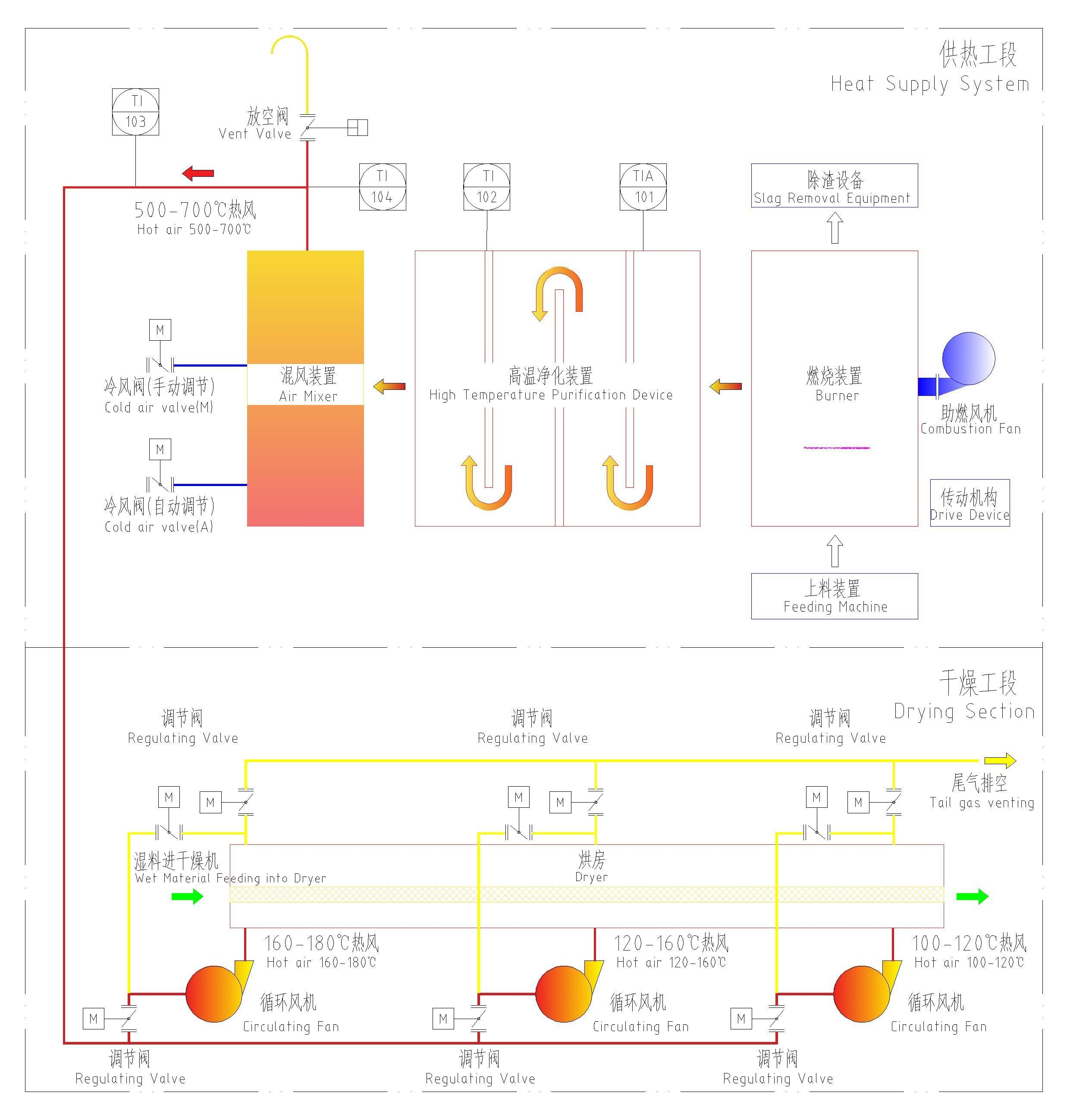

Our company's rubber drying - dedicated hot air furnace has successfully overcome this challenge. It effectively increases hot air temperature and thermal efficiency through the circulation and mixing of tail wind and hot air. The hot air furnace consists of a burner, a high - temperature gas purification device, and an air mixing device, with a scientific and efficient rubber drying process: Fuel enters the silo at the end of the burner through a feeder (with adjustable material layer height) and is uniformly fed into the burner by a transmission mechanism. It fully contacts and burns with the air supplied by the combustion - supporting fan to generate high - temperature flames. The high - temperature flames enter the high - temperature gas purification device for secondary combustion, and the dust carried in the flue gas undergoes melting, polymerization, and sedimentation in the high - temperature purification device. The high - temperature air (~1000℃) from the purification chamber enters the air mixing device and fully mixes with the normal - temperature air from the outside to form hot air at 500 - 700℃. The hot air passes through the circulation fan and mixes with the tail wind drawn from various parts of the drying room to form hot air at a temperature suitable for rubber drying, which then enters the drying room to uniformly dry the materials. Considering the change in material moisture content, when the materials first enter the drying room with high moisture content, the hot air temperature can be appropriately increased to 160 - 180℃, and then gradually decreased. The hot air temperature at the outlet of the drying room is the lowest, approximately 100 - 120℃.

In addition, in response to the rapidly growing market demand for new energy vehicles, a local enterprise in Qingdao launched the latest "fully explosion - proof" safety tire at the expo. This tire uses special support rubber and can still travel at a speed of 60 kilometers per hour for more than 30 kilometers even in a state of zero tire pressure or air shortage, providing solid protection for the safe driving of new energy vehicles and becoming a major highlight of the expo.

This hot air furnace of our company uses coal or biomass pellets as fuel, significantly reducing fuel costs. Moreover, after purification by the high - temperature purification chamber, the dust content in the hot air is less than 120mg/Nm³, which does not affect product quality. At the same time, the air temperature in each part of the drying room can be adjusted, maximizing thermal efficiency. The rubber produced using this furnace has a uniform color and excellent quality, winning wide recognition from participating customers.

The successful holding of this Qingdao Asia - Pacific Rubber & Plastics Expo not only showcased the latest technologies and products in the rubber and tire industry but also provided valuable exchange and cooperation opportunities for enterprises in the industry, which is of great significance for promoting the development of the global rubber and tire industry.