Welcome To CB Piping System Co., ltd., ...

Heat-exchanging (indirect) Biomass (Coal) Fired Hot Air Furnace

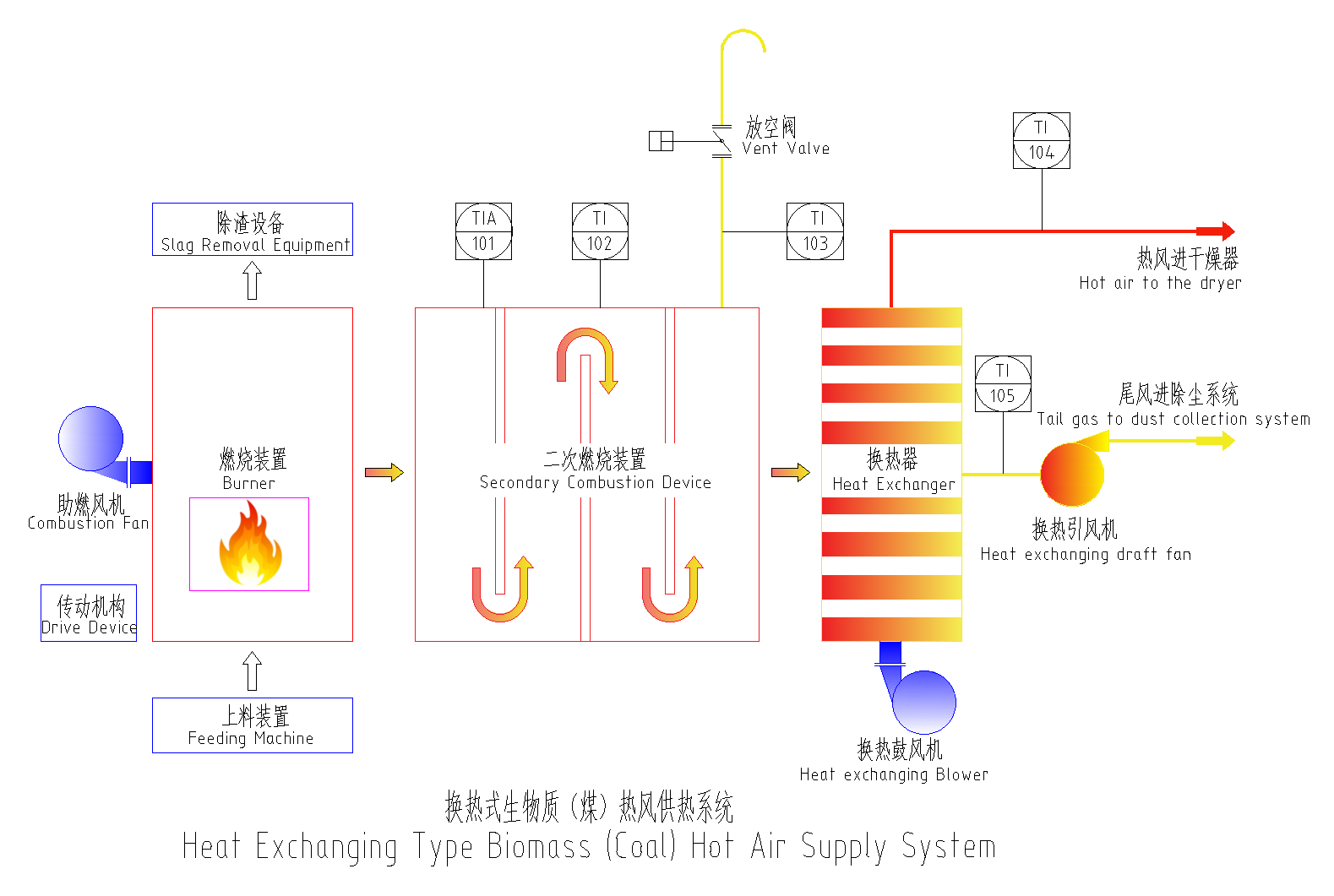

The indirect-fired (biomass/coal) hot air furnace consists of the burner, high-temperature gas secondary combustion device and heat exchanger.

Category:

Products

Working Principle

The indirect-fired (biomass/coal) hot air furnace consists of the burner, high-temperature gas secondary combustion device and heat exchanger.

The fuel is fed into the hopper at the end of the burner through a feeding machine, with adjustable fuel layer height. The fuel is uniformly fed into the burner by a transmission mechanism, where it fully mixes with air supplied by the combustion fan. The fuel produces high-temperature flame after burning in the burner.

The high-temperature flame enters the high-temperature gas purification device for secondary combustion. The flue gas undergoes secondary combustion in the purification device, allowing incomplete combusted carbon black particles in the flue gas to burn completely in this area. The high-temperature air (~1000°C) from the purification chamber mixes thoroughly with external ambient air (or part of the flue gas from the heat exchanger outlet) to reach about 850°C gas before entering the heat exchanger.

Under normal operating conditions, the flue gas flows outside the heat exchanging tubes while air flows inside the tubes. Heat exchanging occurs through counter-flow or cross-flow between the air and flue gas. The heat exchange air is delivered into the tubes by a power delivery device, with its volume adjustable via the fan. The flue gas volume can be regulated by the exhaust fan. The required temperature of the heat exchange air can be controlled by adjusting the exhaust fan frequency appropriately.

Technical Advantages

- Complete combustion with smokeless hot air output

- Secondary combustion device reduces localized overheating damage to heat exchange tubes

- Flexible design of heat exchange tube structure (jet flow, convection, etc.) according to process temperature requirements

- Durable equipment with low operating costs

- Heat exchange efficiency is above 85%

Application Scope

Mainly used for pharmaceutical industry, food industry, high-end feed industry, lithium battery industry, pesticides and dyes.

Key words:

Heat-exchanging (indirect) Biomass (Coal) Fired Hot Air Furnace

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products

Direct Biomass (Coal) Fired Hot Air Furnace

The direct-fired hot air furnace consists of a the burner, high-temperature gas purification device, and air mixing device.

Heat-exchanging (indirect) Biomass (Coal) Fired Hot Air Furnace

The indirect-fired (biomass/coal) hot air furnace consists of the burner, high-temperature gas secondary combustion device and heat exchanger.

Direct Oil/Gas Fired Hot Air Furnace

Direct Oil/Gas Fired Hot Air Furnace is mainly composed of the burner, furnace body and control system. The burner adopts imported integrated burner. Fuel and air enter the furnace body at a certain ratio and burn completely inside. Ambient air passes through the furnace jacket and mixes with high-temperature flue gas to obtain clean flue gas at required process temperature. Single unit heat supply capacity: 50-200x10<sup>4</sup> Kcal/h. Heat supply temperature ≤1000°C.

Spray drying is one of the most widely used processes in liquid forming and drying process. It is suitable for producing powdered or granular solid products from raw materials such as solutions, emulsions, suspensions, and pastes.