Welcome To CB Piping System Co., ltd., ...

Spray drying production line

Spray drying is one of the most widely used processes in liquid forming and drying process. It is suitable for producing powdered or granular solid products from raw materials such as solutions, emulsions, suspensions, and pastes.

Category:

Products

Process Introduction

Spray drying is one of the most widely used processes in liquid forming and drying process. It is suitable for producing powdered or granular solid products from raw materials such as solutions, emulsions, suspensions, and pastes.

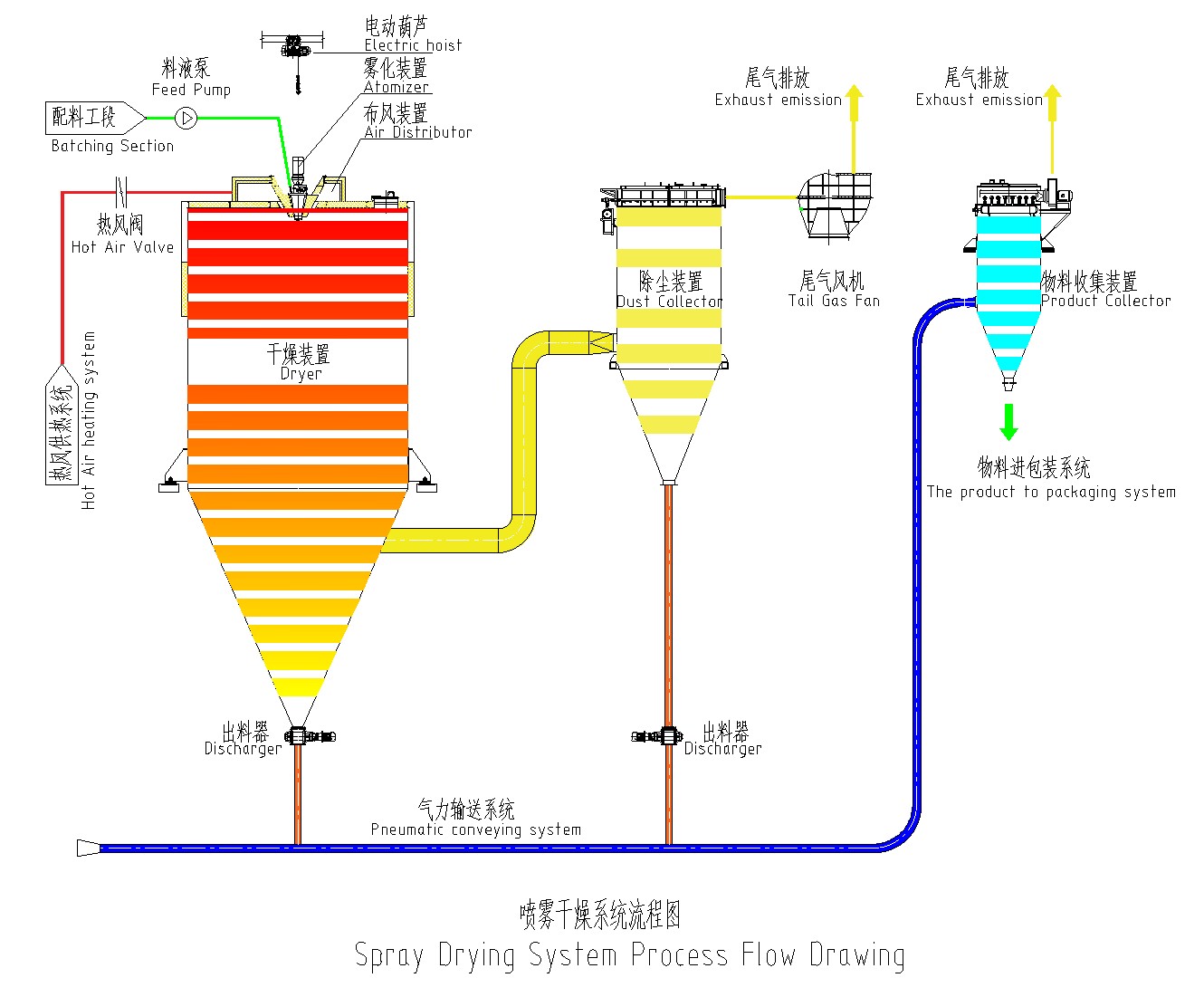

This process consists of raw material feeding system, heating system, hot air supply system, drying system, product collection system, and exhaust gas treatment system.

- Raw Material Feeding System: it transports slurry with varying moisture content into the dryer via conveying equipment, then atomizes the liquid into fine droplets and sprays them into the drying tower.

- Drying System: Evaporates moisture from the raw material to achieve the desired product moisture content.

- Hot Air Supply System: Fully combusts fuel (natural gas, biomass, coal, etc.) in the burner, then mixes it with a certain amount of ambient air or partially recycled exhaust gas to form process air that meets technical requirements. For energy efficiency, part of the exhaust gas from the dryer is reintroduced into the mixing device, where it combines with high-temperature air from the combustion unit to create the process air needed for drying. Inside the drying tower, the process air thoroughly contacts the atomized droplets, which rapidly dry (within 5–40 seconds) into products meeting process specifications.

After leaving the drying tower, the product first enters a conveying pipeline, where it cools before reaching the collection device. Qualified products are then sent to the packaging system.

The Exhaust Gas Treatment System directs the tail gas discharged from the dryer into the processing unit. After purification treatment, all emission indicators fully comply with local environmental protection requirements.

Technical Advantages

- Complete fuel combustion, smokeless hot air.

- High cleanliness of hot air, with dust content at 3~100 mg/Nm³ (combustion and purification processes can be selected as needed).

- Easy adjustment of hot air temperature; process air temperature is fully controllable with stability within ±5°C.

- Durable equipment with low operating costs.

Application Scope

- Chemicals: Dyes, pigments, dye intermediates, compound fertilizers, white carbon black, etc.

- Plastics: ABS emulsion, phenolic resin, polyethylene, polyvinyl chloride, etc.

- Food: Egg white, egg yolk, blood meal, cocoa milk powder, protein, soybeans, corn starch, glucose, etc.

- Ceramics: Ceramic body powder, alumina, talc powder, etc.

Key words:

Spray drying production line

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products

Direct Biomass (Coal) Fired Hot Air Furnace

The direct-fired hot air furnace consists of a the burner, high-temperature gas purification device, and air mixing device.

Heat-exchanging (indirect) Biomass (Coal) Fired Hot Air Furnace

The indirect-fired (biomass/coal) hot air furnace consists of the burner, high-temperature gas secondary combustion device and heat exchanger.

Direct Oil/Gas Fired Hot Air Furnace

Direct Oil/Gas Fired Hot Air Furnace is mainly composed of the burner, furnace body and control system. The burner adopts imported integrated burner. Fuel and air enter the furnace body at a certain ratio and burn completely inside. Ambient air passes through the furnace jacket and mixes with high-temperature flue gas to obtain clean flue gas at required process temperature. Single unit heat supply capacity: 50-200x10<sup>4</sup> Kcal/h. Heat supply temperature ≤1000°C.

Spray drying is one of the most widely used processes in liquid forming and drying process. It is suitable for producing powdered or granular solid products from raw materials such as solutions, emulsions, suspensions, and pastes.