Welcome To CB Piping System Co., ltd., ...

Direct Oil/Gas Fired Hot Air Furnace

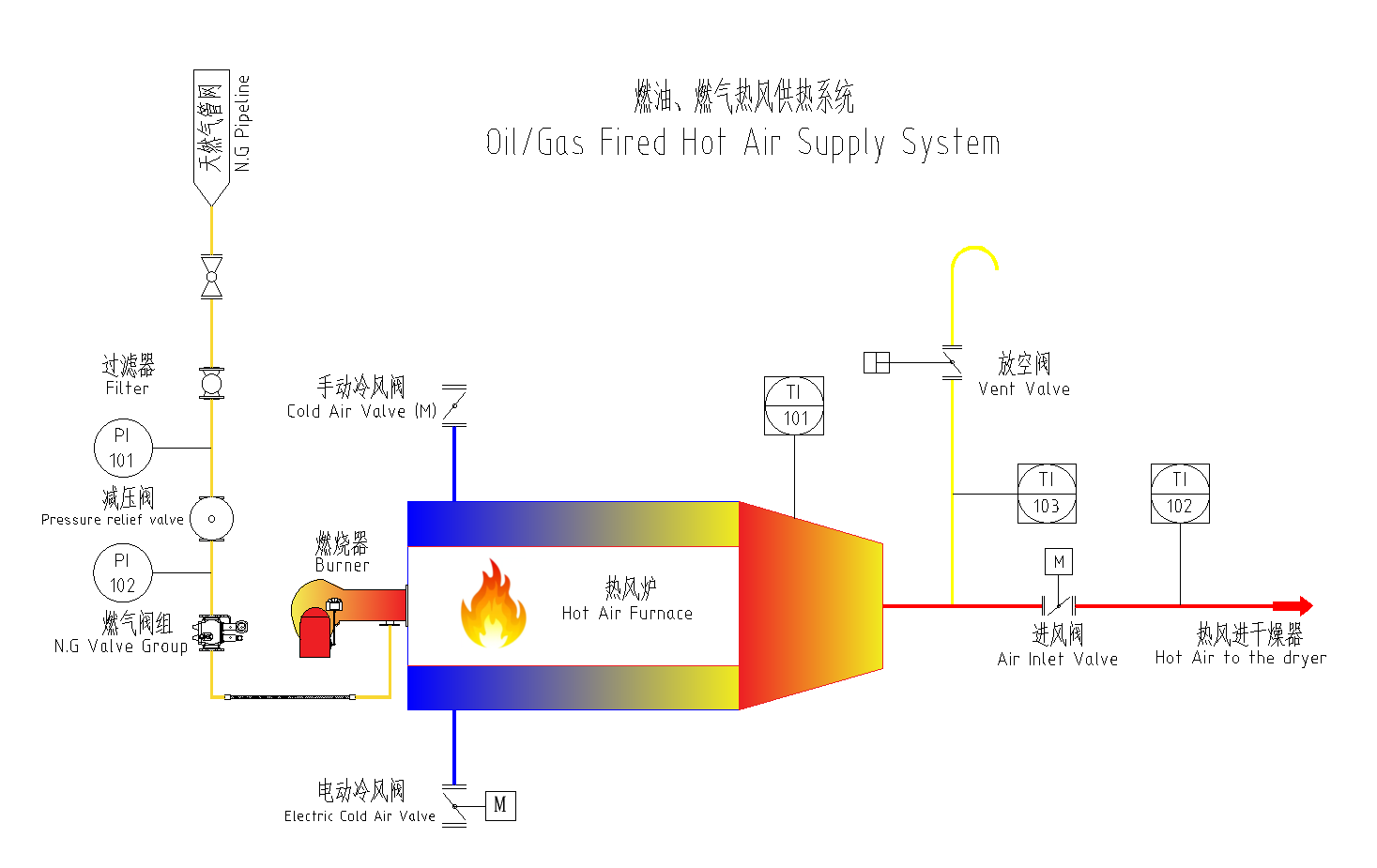

Direct Oil/Gas Fired Hot Air Furnace is mainly composed of the burner, furnace body and control system. The burner adopts imported integrated burner. Fuel and air enter the furnace body at a certain ratio and burn completely inside. Ambient air passes through the furnace jacket and mixes with high-temperature flue gas to obtain clean flue gas at required process temperature. Single unit heat supply capacity: 50-200x104 Kcal/h. Heat supply temperature ≤1000°C.

Category:

Products

Product Introduction

Direct Oil/Gas Fired Hot Air Furnace is mainly composed of the burner, furnace body and control system. The burner adopts imported integrated burner. Fuel and air enter the furnace body at a certain ratio and burn completely inside. Ambient air passes through the furnace jacket and mixes with high-temperature flue gas to obtain clean flue gas at required process temperature. Single unit heat supply capacity: 50-200x104 Kcal/h. Heat supply temperature ≤1000°C.

The indirect fired hot air furnace is based on direct fired furnace with added plate heat exchanger. High-temperature flue gas exchanges heat with high purity air to obtain high-cleanliness hot air. After heat exchange, flue gas is discharged by induced draft fan while ambient air is sent into heat exchanger by forced draft fan. Heat supply temperature range: 50~450°C.

Technical Characteristics:

- Compact size, less than 1/2 volume of traditional hot air furnace

- Light weight, only 1/3-1/4 of traditional furnace weight. Lower steel consumption and cost

- Complete combustion with clean operation environment; meets environmental standards without secondary pollution

- High cleanliness hot air; convenient temperature adjustment

- Simple operation and easy adjustment

- Equipped with manual/automatic control functions

- Special anti-expansion design for indirect-fired furnace effectively solves thermal expansion issues

- With functions of automatic ignition, load adjustment, flame detection and alarm

Application Scope:

Daily chemicals, ceramics, fertilizers, chemicals, food, pharmaceuticals, feed, environmental protection, building materials, etc.

Key words:

Direct Oil/Gas Fired Hot Air Furnace

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products

Direct Biomass (Coal) Fired Hot Air Furnace

The direct-fired hot air furnace consists of a the burner, high-temperature gas purification device, and air mixing device.

Heat-exchanging (indirect) Biomass (Coal) Fired Hot Air Furnace

The indirect-fired (biomass/coal) hot air furnace consists of the burner, high-temperature gas secondary combustion device and heat exchanger.

Direct Oil/Gas Fired Hot Air Furnace

Direct Oil/Gas Fired Hot Air Furnace is mainly composed of the burner, furnace body and control system. The burner adopts imported integrated burner. Fuel and air enter the furnace body at a certain ratio and burn completely inside. Ambient air passes through the furnace jacket and mixes with high-temperature flue gas to obtain clean flue gas at required process temperature. Single unit heat supply capacity: 50-200x10<sup>4</sup> Kcal/h. Heat supply temperature ≤1000°C.

Spray drying is one of the most widely used processes in liquid forming and drying process. It is suitable for producing powdered or granular solid products from raw materials such as solutions, emulsions, suspensions, and pastes.