Welcome To CB Piping System Co., ltd., ...

Direct Biomass (Coal) Fired Hot Air Furnace

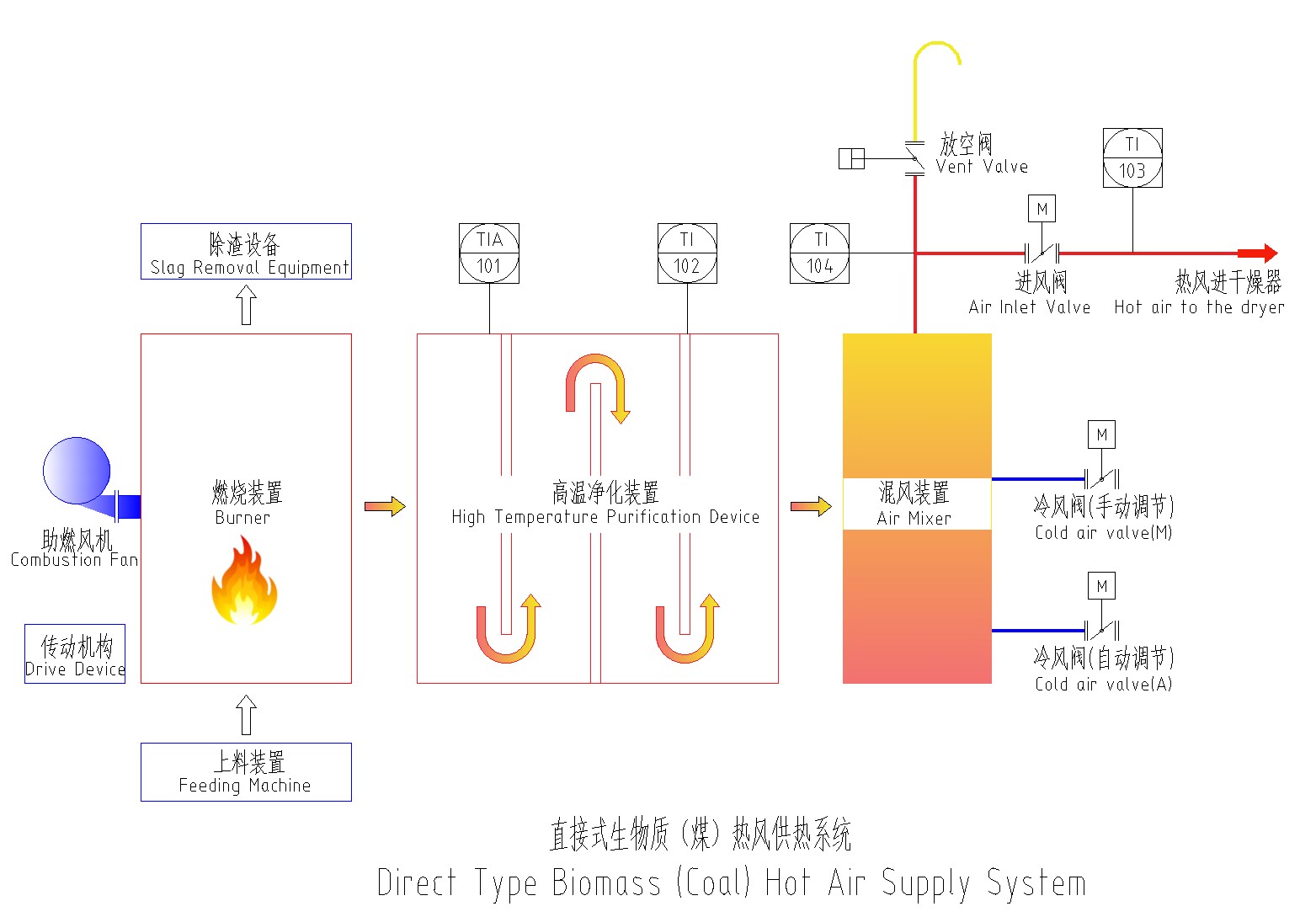

The direct-fired hot air furnace consists of a the burner, high-temperature gas purification device, and air mixing device.

Category:

Products

Working Principle

The direct-fired hot air furnace consists of the burner, high-temperature gas purification device, and air mixing device.

The fuel is fed into the hopper at the end of the burner through a feeding machine, with adjustable fuel layer height. The fuel is uniformly fed into the burner by a transmission mechanism, where it fully mixes with air supplied by the combustion-supporting fan. The fuel produces high-temperature flame after burning in the burner.

The high-temperature flame enters the high-temperature gas purification device for secondary combustion. The dust carried in the flue gas undergoes melting, aggregation and sedimentation in the high-temperature purification device. The high-temperature air (~1000°C) from the purification chamber enters the mixing device and is thoroughly mixed with ambient air (from external air source) to achieve the required process temperature before entering drying equipment (spray tower, rotary dryer, fluidized bed, etc.) for material drying.

Technical Advantages

- Complete combustion with smokeless hot air output

- High air purity with dust content of 10-150mg/Nm³, purification process can be selected according to requirements

- Convenient temperature adjustment with stability of ±3°C at 400°C operating condition

- Durable equipment with low operating costs

- Combustion thermal efficiency exceeds 97%

Application Scope

Daily Chemicals: Detergent powder, 4A zeolite, etc.

Ceramics: Ceramic body powder (polished tiles), tile base material, kaolin, etc.

Fertilizers: Potassium chloride, potassium sulfate, compound fertilizer, MAP, DAP, etc.

Chemicals: PAC, PFS, dyes, calcium chloride, etc.

Feed: Dicalcium phosphate, distiller's grains, DDGS, etc.

Building Materials: Quartz sand, FGD gypsum, ceramic insulation wool, etc.

Others: Rubber, paper black liquor, lignite, briquettes, wood chips, etc.

Key words:

Direct Biomass (Coal) Fired Hot Air Furnace

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products

Direct Biomass (Coal) Fired Hot Air Furnace

The direct-fired hot air furnace consists of a the burner, high-temperature gas purification device, and air mixing device.

Heat-exchanging (indirect) Biomass (Coal) Fired Hot Air Furnace

The indirect-fired (biomass/coal) hot air furnace consists of the burner, high-temperature gas secondary combustion device and heat exchanger.

Direct Oil/Gas Fired Hot Air Furnace

Direct Oil/Gas Fired Hot Air Furnace is mainly composed of the burner, furnace body and control system. The burner adopts imported integrated burner. Fuel and air enter the furnace body at a certain ratio and burn completely inside. Ambient air passes through the furnace jacket and mixes with high-temperature flue gas to obtain clean flue gas at required process temperature. Single unit heat supply capacity: 50-200x10<sup>4</sup> Kcal/h. Heat supply temperature ≤1000°C.

Spray drying is one of the most widely used processes in liquid forming and drying process. It is suitable for producing powdered or granular solid products from raw materials such as solutions, emulsions, suspensions, and pastes.