Welcome To CB Piping System Co., ltd., ...

Quartz Sand Drying production line

The triple-pass rotary dryer is mainly used in industrial production for drying all granular, non-sticky, free-flowing materials such as quartz sand, yellow sand, clay, slag, coal, iron powder, etc. It is also suitable for drying bulk materials in compound fertilizer, phosphate fertilizer, and metallurgy industries.

Category:

Products

Product Introduction:

The triple-pass rotary dryer is mainly used in industrial production for drying all granular, non-sticky, free-flowing materials such as quartz sand, yellow sand, clay, slag, coal, iron powder, etc. It is also suitable for drying bulk materials in compound fertilizer, phosphate fertilizer, and metallurgy industries.

The triple-pass rotary dryer is constructed by assembling three cylinders of different diameters together based on the single-pass rotary dryer. It generally adopts roller transmission, driven by 2-4 motors, and synchronized by a frequency converter. The cylinder is horizontally installed without inclination, making installation relatively simple and requiring a small footprint.

The middle and outer cylinders of the triple-pass rotary dryer are completely sealed, significantly improving thermal efficiency. During design and manufacturing, factors such as equipment material and the sturdiness of lifting plates are fully considered. With reasonable design and fine workmanship, the service life of the triple-pass rotary dryer is greatly extended.

Main Features:

- The initial moisture content of materials is 15%, and the final moisture content is guaranteed to be below 0.5-1%, making it a reliable choice for cement plants, slag micropowder, and dry-mix mortar production lines.

- The cylinder has self-insulation, with thermal efficiency as high as 80~85%. The outer cylinder wall temperature is below 60℃, significantly saving fuel compared to single-pass dryers.

- The equipment's length is reduced by 60% compared to single-pass dryers, occupying less space and benefiting overall process layout.

- The discharge temperature is <50℃, allowing direct entry into the storage silo.

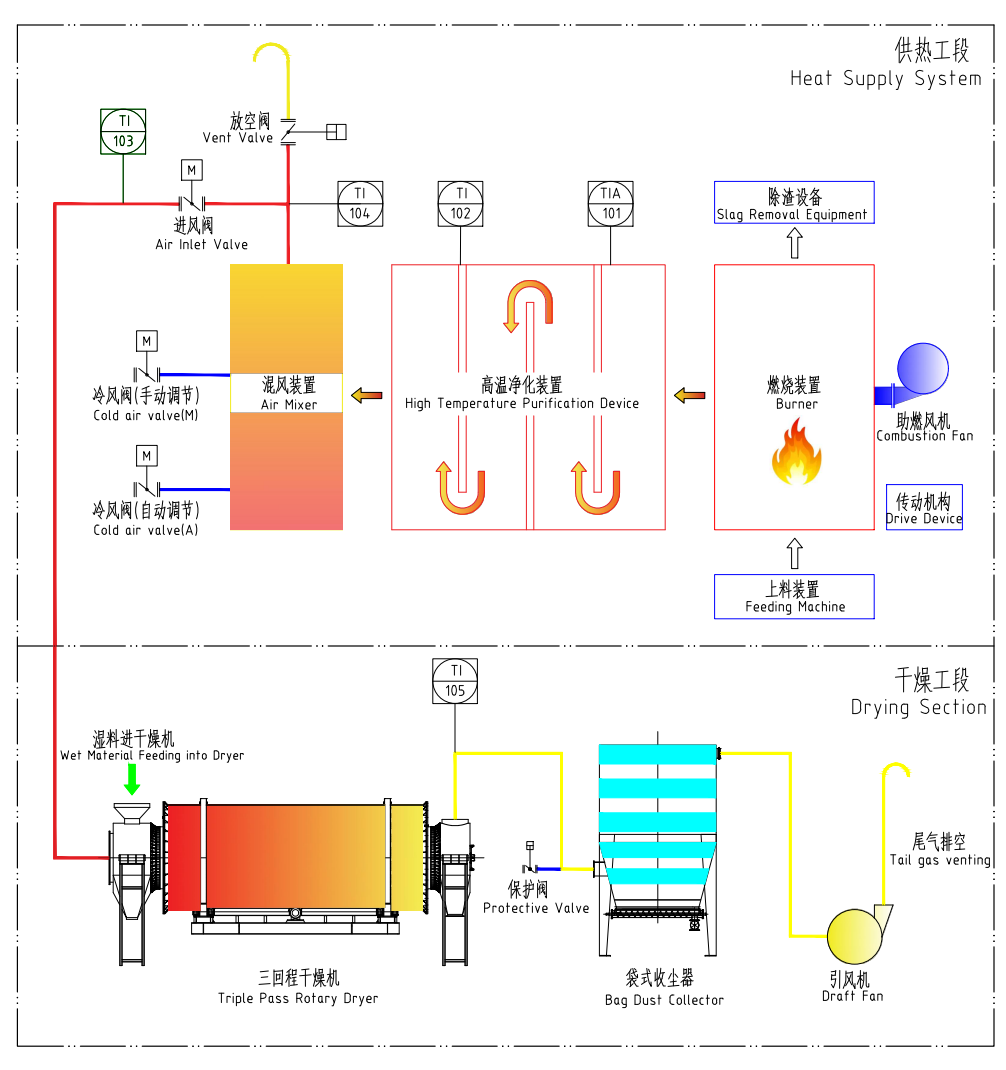

The Quartz Sand Drying Production Line is a high-efficiency industrial system designed for continuous drying of quartz sand in large-scale operations. Constructed with durable, corrosion-resistant materials, it ensures stable performance under high-temperature conditions. The line integrates feeding, drying, cooling, screening, and discharge processes, providing seamless material flow and minimal manual handling. Advanced temperature control and airflow management maintain consistent moisture content, preserve sand quality, and optimize energy consumption. Ideal for glass, foundry, construction, and chemical industries, this system improves production efficiency, reduces operational costs, and delivers high-quality dried quartz sand suitable for various industrial applications.

Key words:

Quartz Sand Drying production line

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products

Direct Biomass (Coal) Fired Hot Air Furnace

The direct-fired hot air furnace consists of a the burner, high-temperature gas purification device, and air mixing device.

Heat-exchanging (indirect) Biomass (Coal) Fired Hot Air Furnace

The indirect-fired (biomass/coal) hot air furnace consists of the burner, high-temperature gas secondary combustion device and heat exchanger.

Direct Oil/Gas Fired Hot Air Furnace

Direct Oil/Gas Fired Hot Air Furnace is mainly composed of the burner, furnace body and control system. The burner adopts imported integrated burner. Fuel and air enter the furnace body at a certain ratio and burn completely inside. Ambient air passes through the furnace jacket and mixes with high-temperature flue gas to obtain clean flue gas at required process temperature. Single unit heat supply capacity: 50-200x10<sup>4</sup> Kcal/h. Heat supply temperature ≤1000°C.

Spray drying is one of the most widely used processes in liquid forming and drying process. It is suitable for producing powdered or granular solid products from raw materials such as solutions, emulsions, suspensions, and pastes.