Welcome To CB Piping System Co., ltd., ...

Lignite Drying production line

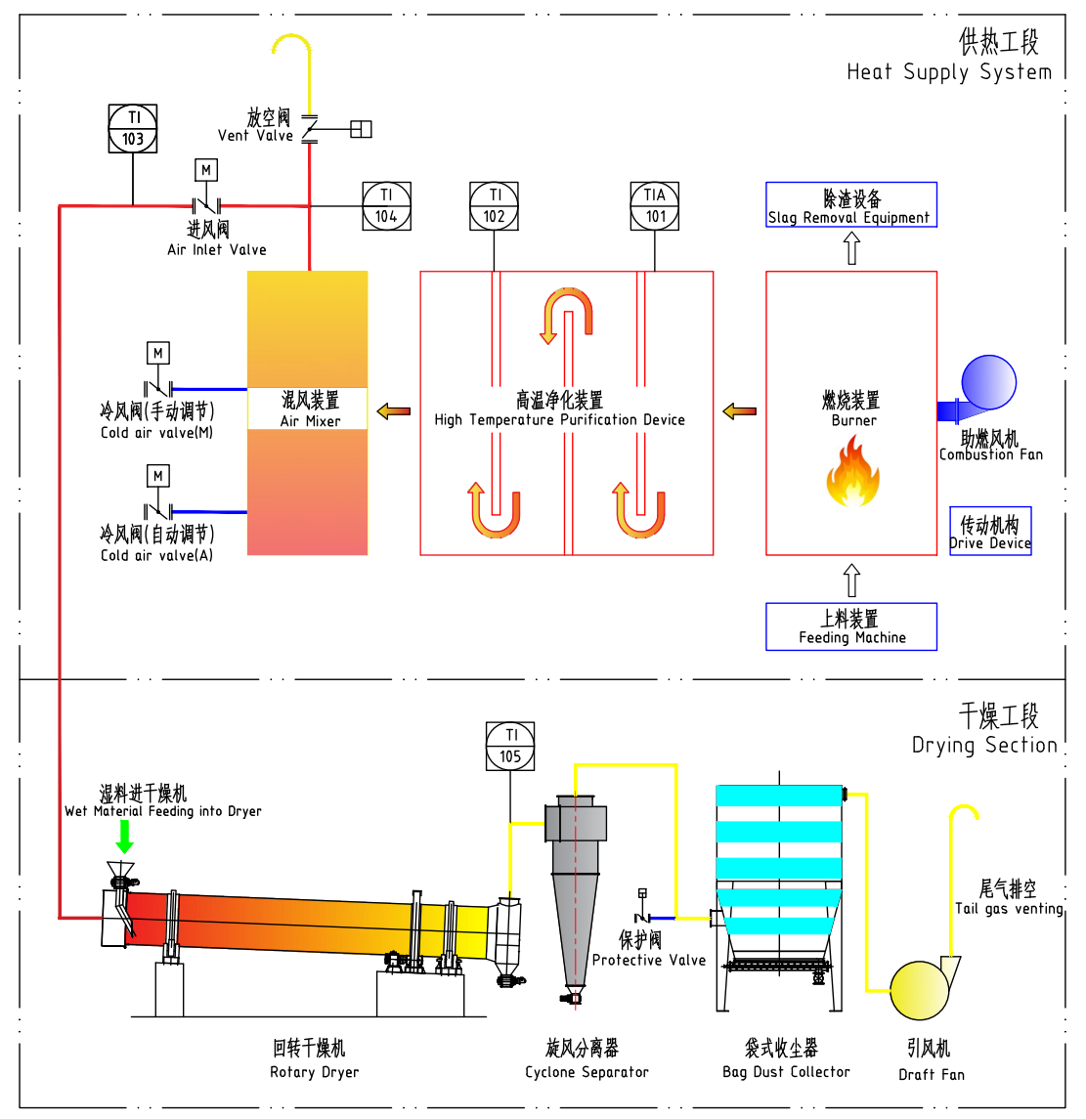

This process consists of raw material conveying system, heating system, hot air supply system, drying system and exhaust gas treatment system.

Category:

Products

Process Introduction

This process consists of raw material conveying system, heating system, hot air supply system, drying system and exhaust gas treatment system.

The raw material conveying system transports raw materials with 30~40% moisture content into the dryer through conveying equipment.

The drying system is responsible for evaporating moisture from the raw materials to achieve the required product moisture content.

The hot air supply system consists of burner, high-temperature gas purification device and air mixing device. The burner is responsible for fuel combustion, the high-temperature gas purification device ensures cleanliness of drying flue gas, and the air mixing device maintains drying air temperature to meet process requirements (approximately 300~600℃).

The hot air supply system delivers process air into the dryer. For energy saving, part of the exhaust gas after drying is introduced into the air mixing device and blended with high-temperature air from the purification device to form the required process air for drying.

The exhaust gas treatment system processes the exhaust gas from the dryer to meet local environmental protection standards.

Technical Advantages

Complete combustion with smokeless hot air.

High cleanliness of hot air with dust content of 50~200mg/Nm3, purification process can be selected as required.

Convenient temperature adjustment of hot air, adjustable between 300~600℃ with temperature stability of ±3℃.

Durable equipment with low operating costs.

Combustion thermal efficiency exceeds 97%, achieving significant energy savings.

Lignite drying production line is a complete industrial system designed to reduce the high moisture content of lignite coal and improve its calorific value, storage stability, and combustion performance. Lignite, also known as brown coal, typically contains a high level of inherent and surface moisture, which limits its heating efficiency and increases transportation and handling costs. A dedicated drying production line addresses these challenges by removing excess moisture in a controlled, energy-efficient, and continuous process.

The production line usually consists of raw material feeding equipment, crushing and screening units, drying system, hot air furnace or heat source, dust collection system, conveying devices, and an automatic control system. Wet lignite is fed into the system and evenly distributed to ensure stable processing. Depending on project requirements, drying equipment such as rotary dryers, fluidized bed dryers, or belt dryers may be used to achieve efficient heat transfer and uniform moisture removal.

Heat for the drying process is provided by hot air generated from sources such as gas, biomass, coal, or waste heat recovery systems. Temperature, airflow, and residence time are precisely controlled to prevent over-drying or ignition while ensuring consistent final moisture content. Advanced control systems allow real-time monitoring and adjustment, improving safety, energy efficiency, and product consistency.

After drying, lignite exhibits reduced moisture content, higher heating value, improved grindability, and better combustion stability. This makes the dried lignite more suitable for power generation, industrial boilers, gasification, and briquette production. The drying process also reduces transportation weight, lowering logistics costs and improving overall economic efficiency.

Environmental protection is an important aspect of lignite drying production lines. Modern systems are equipped with dust collectors, cyclones, bag filters, and emission control devices to minimize dust and exhaust gas emissions. Optimized heat utilization and insulation design reduce fuel consumption, supporting cleaner and more sustainable operation.

Overall, a lignite drying production line provides an effective solution for upgrading low-grade coal resources. It enhances fuel quality, improves energy utilization efficiency, reduces operating costs, and supports stable, large-scale industrial applications. With reliable operation, flexible configuration, and high automation, lignite drying production lines play a key role in the efficient and responsible use of lignite in modern energy and industrial systems.

Key words:

Lignite Drying production line

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products

Direct Biomass (Coal) Fired Hot Air Furnace

The direct-fired hot air furnace consists of a the burner, high-temperature gas purification device, and air mixing device.

Heat-exchanging (indirect) Biomass (Coal) Fired Hot Air Furnace

The indirect-fired (biomass/coal) hot air furnace consists of the burner, high-temperature gas secondary combustion device and heat exchanger.

Direct Oil/Gas Fired Hot Air Furnace

Direct Oil/Gas Fired Hot Air Furnace is mainly composed of the burner, furnace body and control system. The burner adopts imported integrated burner. Fuel and air enter the furnace body at a certain ratio and burn completely inside. Ambient air passes through the furnace jacket and mixes with high-temperature flue gas to obtain clean flue gas at required process temperature. Single unit heat supply capacity: 50-200x10<sup>4</sup> Kcal/h. Heat supply temperature ≤1000°C.

Spray drying is one of the most widely used processes in liquid forming and drying process. It is suitable for producing powdered or granular solid products from raw materials such as solutions, emulsions, suspensions, and pastes.